Loadsensing

LOADSENSING - CONNECTED OPERATIONAL INTELLIGENCE

A Wireless Monitoring System that gives Royal Technergy expert advantage

Because we are your reliable partner, we are poised to proffer unbeatable SOLUTIONS.

At Royal Technergy we believe that completing required tasks on time and within budget, we have become successful.

We pave the way towards more connected and operationally intelligent companies in the future.

Loadsensing – supplied exclusively to Royal Technergy – is a digital system for digitalizing monitoring processes to increase efficiency, reduce costs, ensure workforce safety and match global standards.

The Wireless Monitoring System

Monitoring how structures evolve

Loadsensing is the global leader for connecting and wirelessly monitoring infrastructures in remote locations.

Construction and mining companies and operators of bridges, tunnels, dams, railways and many other inaccessible assets can now work with reliable data. Having access to this information and real-time insights enables operators to anticipate needs, manage their workforce, diminish risks, and even prevent disasters.

The wireless configuration also eliminates the need for manual monitoring and expensive cabling thus contributing to savings.

Applications

- Civil Engineering

- Linear Infrastructure Monitoring (LIM)

- tunnels, roads, railways

- Structural Health Monitoring (SHM)

- dams, bridges and buildings

- Geotechnical Monitoring

- Linear Infrastructure Monitoring (LIM)

- Mining

- Open pit and underground mines

- Tailings dams

- Geological hazards monitoring

Around-the-Clock Monitoring

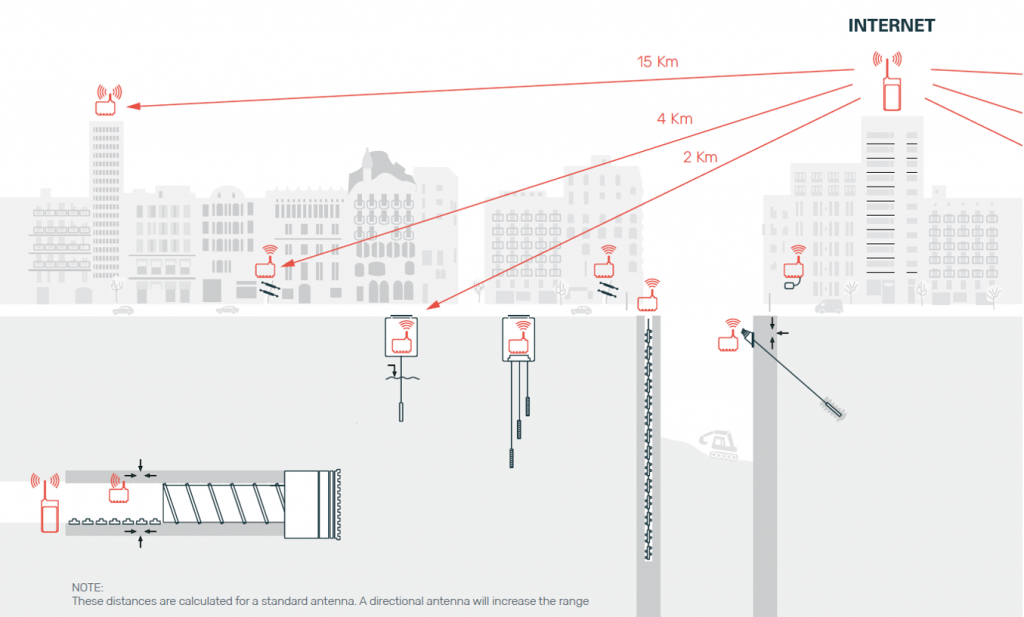

Loadsensing is a long-range and ultra low-power wireless data acquisition system for sensor networks.

The wireless system creates dynamic smart sensor networks which can be easily deployed in difficult-to-access sites.

The end-to-end solution is technically robust, easy-to-use, enjoys longevity and helps to create safer environments and peace of mind.

Benefits of Wireless Monitoring System for Operational Intelligence

1

2

3

4

Increased efficiency

Work with an end-to-end solution from field to control centre. Manual and visual inspections are not necessary. Optimize maintenance cycles and reduce them to ad-hoc check-ups. Use a smartphone APP to monitor processes.

Faster ROI

Save time, nerves and spendings on expensive added equipment or staff. Save km of cables and keep installation and maintenance costs down.

Workforce safety

Leverage 24/7 remote information which allows users to anticipate problems and thus avert cost-intensive accidents. Rely on alarm capabilities to prevent structural stress.

Global standards

Establish a positive public image as a company that is at par with global standards in safety, efficiency and technology.

- We design, construct, supply, install and provide technical support